|

It is ideal for use:

Alphatec® is only suitable for coastal environments >500m from the high tide line and are NOT suitable in strongly acidic or caustic environments so PH must be >5 and <9.

Alphatec®

Superior: 5

Excellent: 4

Very good: 3

Good: 2

OK: 1

Not Applicable: 0

Visit the contact us page to get in touch.

The pre-treatment process must be capable of meeting the performance outputs as described in AS3715. Compliance to appropriate process parameters is essential in ensuring compliance to etch, conversion coating weights (time/concentration) and conductivity of the final rinse.

The etch process is a very important stage of pre-treatment and close consultation with your pre-treatment supplier is strongly recommended to ensure optimum adhesion & corrosion resistance is obtained. As an approximate guide:

This is the next pre-treatment process for aluminium to ensure that it is suitably prepared for coating. It is recommended that Chrome conversion weights shall be a minimum of 431mg/m2, but advice from pre-treatment suppliers should be taken into consideration.

Final rinse is to ensure optimum surface preparation prior to coating.

Care should be taken with handling to ensure health and safety measures are met and that the substrate is not contaminated.

If your site uses a dry off oven to assist in the pre-treatment process, consult your pre-treatment supplier for advice, but generally;

Steel substrates shall be prepared as follows:

1. Wash and degrease all surfaces to be coated in accordance with AS1627.1 with a free-rinsing, alkaline detergent, in strict accordance with the manufacturer’s written instructions and all safety warnings.

2. Wash with fresh potable water and ensure that all soluble salts are removed in accordance with AS 3894.6 methods A&D.

3. Grind all sharp edges with a power tool to a minimum radius of 2mm.

4. Power tool clean welds to AS1627.2 Class 2 to remove roughness. Remove filings, preferably by vacuum or compressed air.

5. Abrasive blast clean all steel surfaces to be painted in accordance with AS1627.4 to visual standard AS1627.9 Class 2.5 (equivalent to ISO8501-1, Sa 2.5: Very Thorough Blast-Cleaning). Use a medium that will generate a surface profile of 35 to 65 microns (as tested to AS3894.5 Method A.) In situations where it is not possible to prepare your item on all surfaces as described above, for long term protection against corrosion it is strongly recommended whenever possible, that an alternative substrate such as, aluminium be considered.

6. The steel is to be stored in an area which is clean and dry

7. The steel must be coated within 4 hours of blasting.

Electrostatic Spray

Metal Temperature:

210° : 4 mins minimum

200° : 5 mins minimum

180° : 8 mins minimum

Metal Temperature:

200° : 2 mins minimum

180° : 5 mins minimum

160° : 10 mins minimum

Please note: All RapidCure products can be applied at standard temperatures, but benefits from possible reduction in energy consumption or faster line speeds will be lost.

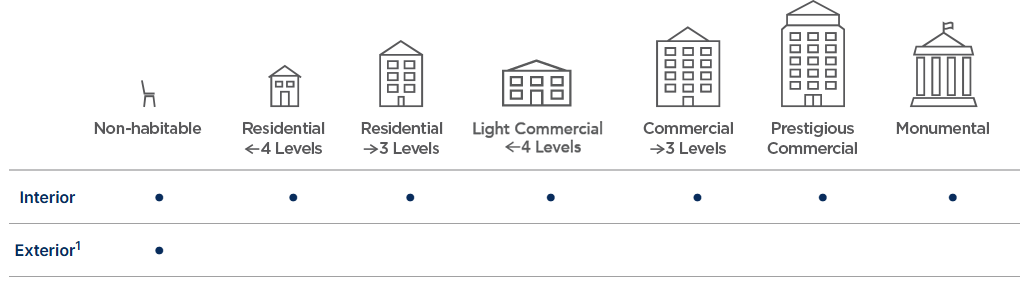

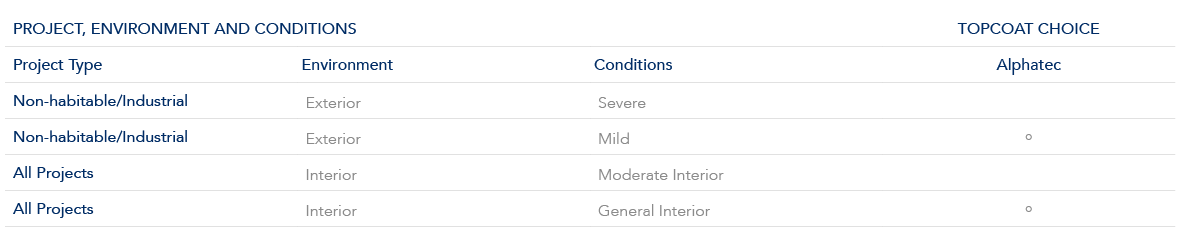

Use the following table to help identify where Alphatec can be applied on aluminium projects. Refer to the conditions information to determine the environment that your project will be exposed to.

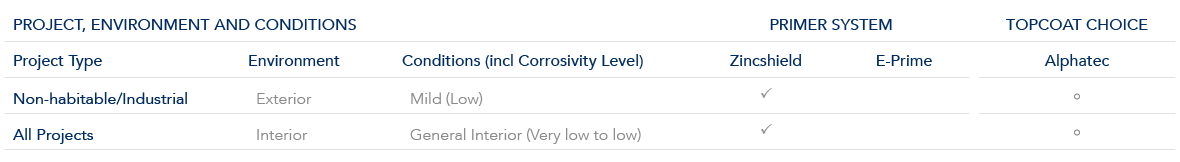

Use the following table to help identify where Alphatec can be applied on steel projects. Refer to the conditions information to determine the environment that your project will be exposed to.

Alphatec is only suitable for coastal environments >500m from the high tide. All Dulux powder products are NOT suitable in strongly acidic or caustic environments so PH must be >5 and <9.

Use the following table which references AS2312.1, AS 4312 and ISO 9223 to identify the environment, conditions and atmospheric corrosivity categories to pinpoint your projects corrosivity zone this table should be used together with the corrosivity zone maps contained within AS 4312.

Our dedicated consultants can help simplify the specification process, saving you time and money by providing the right coating advice for your project. Call 13 24 99 For a comprehensive overview and specific specification details on aluminium and steel click here.

Colours displayed should be used as a guide for your colour selection.

Always confirm your colour choice with a production line prepared swatch for final colour approval.

The Alphatec® range has fun, bright solid colours for a big impact delivered with tough polyester thermosetting powder.

Gloss

98432120

Gloss

9844480G

Gloss

98419941

Satin

9846538S

Gloss

98433617

Gloss

9844481G

Gloss

98432725

Gloss

98451040

Gloss

9842015G

Gloss

98419959

Gloss

98451034

Gloss

9846536G

Gloss

9844207G

Gloss

9844461G

Gloss

98419990

Gloss

98451926